Key Points for the Practical Project of Mobile Phone Case Processing by Injection Molding Machine

In the digital age, smartphones have become indispensable to people’s lives. With the continuous advancement of technology and the increasing demand of consumers for personalized products, the mobile phone case market has shown great development potential. Mobile phone cases are very promising for those who want to start a small business. Whether it is online sales or offline physical stores, mobile phone cases can meet the needs of different consumers. In addition, the production process of mobile phone cases is relatively simple, with low initial investment, which is suitable for first-time entrepreneurs.

Mobile Phone Case Market Prospects and Demand Analysis

The market size and development trend of the mobile phone case industry show strong growth momentum. The main consumer groups in the mobile phone case market are mainly young people, especially female users. According to relevant reports, mobile phone cases have high user stickiness, with more than 10 million users purchasing more than 12 times a year. Among these loyal users, female users account for a considerable proportion, and it can even be said that they “hold up half the sky”. In addition, young groups are an important force in promoting the development of the mobile phone case industry. Modern people cannot live without smartphones, and mobile phone cases, as a protective tool, have become a rigid demand. The Chinese habit of wearing cases for mobile phones is also related to the tradition of frugality. Many people choose to use mobile phone cases to protect their mobile phones from defects or damage. In terms of purchasing habits, consumers in the mobile phone case market usually match a tempered film to protect the screen and a mobile phone case to protect the mobile phone for a short period of time.

Preparation for Mobile Phone Case Production

Opening a small mobile phone case factory requires the following equipment and materials: injection molding machine, basic mobile phone cases of different colors, UV printer and water transfer equipment.

Injection molding machine is the core equipment for producing mobile phone cases. Common injection molding machine models include Haitian, Zhenxiong, Donghua and other brands. If the 200T machine meets the requirements for clamping force and machine size, but the injection volume does not meet the product weight requirements, a larger model should be selected, such as a 250-300T machine. An efficient injection molding machine may be able to produce hundreds of mobile phone cases per hour, and the specific speed depends on the design of the mold and the setting of injection molding parameters. To ensure the quality control of the injection molding machine, the quality of raw materials should be strictly controlled, professional training should be carried out for the injection molding machine, and the injection molding machine should be regularly maintained. These are all based on production needs and budgets. Operators need to wear personal protective equipment, including safety glasses, gloves and protective clothing. Then, open the cooling water valve, ensure that the water channel is unobstructed, turn off the power switch on the side of the control box, turn on the power inside the machine, and press the motor start button on the panel to start the oil pump motor. Before the injection molding machine is heated and starts production, add the raw materials and set the parameters, including temperature, injection pressure, injection speed, etc. When the temperature reaches the set value, turn on the motor and perform injection molding. Multiple mobile phone cases can be produced each time by injection molding, and the specific number depends on the design of the mold and the capacity of the injection molding machine. If there is no injection molding machine, you can choose to cooperate with a company that has already opened a mold and order a batch of mobile phone cases made by injection molding to reduce the initial investment.

The plain mobile phone cases produced by the mold are transparent and colored, white, red, black, etc., and various sizes are prepared according to the popular brand mobile phone model series, such as the sizes of Apple 15 and Huawei Mate60 series. Finally, we have a deep understanding of the user’s demand for mobile phone cases, which can be processed into finished products of different styles, and can also be used for different secondary processing.

Comparison of UV Printing and Water Transfer Printing in Mobile Phone Case Production

UV printing is suitable for mobile phone case production that requires high quality, multi-color and environmental protection, but the cost is high and the operation is risky. Water transfer printing is suitable for mobile phone case production that requires complex patterns and high aesthetics, but the graphics are easily deformed and have limitations.

UV Printing

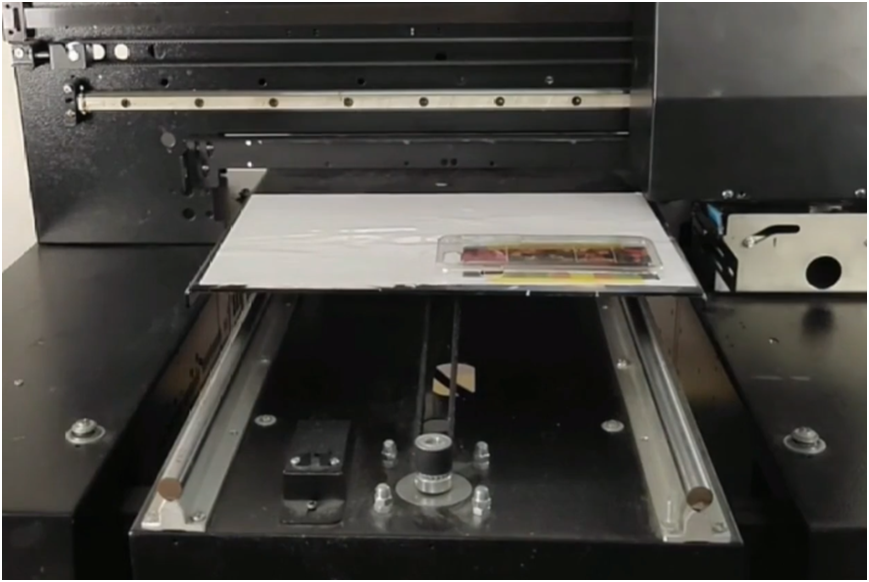

First, paste white paper, adjust the distance between the paper and the height limit to 2-3mm, process the pattern to be printed on the computer drawing software, and do a good job of positioning. One is to print on the paper first, and then fix the mobile phone case with double-sided tape in the printed position, turn on the inkjet switch and UV lamp power. Add the printing medium, turn on the adsorption function power, measure the thickness of the printing medium, adjust the height according to the printed object, and return to the origin. Import the pattern into the UV printer control software and set the PASS channel, feathering value and other parameters. Click the start button, and you can observe from the operating table that the sprayed ink instantly changes from liquid to solid, and the pattern gradually appears on the mobile phone case. After printing, the pattern of the phone case is bright and clear, smooth to the touch, and the ink after UV light curing is integrated with the surface of the phone case, which is durable.

You can choose to print one or more phone cases, and a balance should be achieved between the cost and the equipment to maximize the benefits.

1. The printing precision of producing a phone case is high, there are not too many defects, and no secondary processing is required, but the speed is relatively slow. If it is a small injection molding machine, it can be used, and there is not so much material loss.

2. When you choose to UV print multiple mobile phone cases, try to put multiple patterns in the effective area, so that you can produce multiple mobile phone cases at one time, but the distance between each picture is 2CM. The efficiency is high, but the finished product has defects, so secondary processing is required, which will consume more materials and labor.

UV flatbed printer equipment makes it possible to print DIY mobile phone cases on any material. It is suitable for various printing materials and can print three-dimensional relief 3D effects. It supports a variety of color combinations such as four-color, six-color and white ink. It has excellent friction resistance and good reflection effect. The pattern on the mobile phone case will not fall off or fade easily. However, the production cost is high and the printing speed is slow.

Water Transfer

First, prepare the water transfer pattern. You can buy it in advance or make it yourself. Spray the mobile phone case with primer, which is usually white. Prepare the water-coated film pattern, then take it out and cut it to the appropriate size. Spread these patterned films flat on the water surface and soak them for 15-25 seconds. When the film contacts the water’s surface, you can see that the film slowly begins to unfold and gradually spreads flatly on the water surface. During this process, the pattern on the film appears particularly vivid, as if floating on the water. Then spray a chemical called an activator on the film. You can see that the surface of the film has slight fluctuations, and you will smell a slightly chemical-pungent odor. The addition of the activator makes the film sticky and the pattern becomes easy to transfer to the surface of the object. Then press the case down at an angle to make sure the pattern is flat and there are no bubbles. Finally, take the case out of the water and it is done.

The water transfer process can transfer any natural texture, photos, and images onto the product, giving the product the color of the scenery you want. It can overcome the complex shapes and dead corners that cannot be produced by traditional printing technology. However, if the primer is not dry enough, cracks will occur. If the tape on the transfer film is not properly attached, the ink will overflow, which will deform the pattern. It may also be due to improper operation of the employee, resulting in deviation of the finished product, while UV printing will not have this problem.

What innovative methods can mobile phone case factories use in post-processing and surface treatment to improve the appearance and feel of products?

| Technology Name | Technical Description | Advantage |

| PVD (Physical Vapor Deposition) Technology | Coating a high-hardness, high-wear-resistant metal-ceramic decorative coating on the metal surface | Improve product durability and aesthetics |

| Anodizing Technology | Through multiple processes such as degreasing, alkali washing, neutralization, sandblasting, chemical polishing, oxidation, etc., a dense and hard oxide film is formed on the surface of the aluminum alloy shell. | Make the product more wear-resistant and less prone to stains |

| Plasma surface treatment technology | Improve the wear resistance of mobile phone cases | Prevent paint from falling off or grinding after long-term use; improve the firmness and quality of hot stamping; solve problems such as residual photoresist and grease |

| Ceramic spraying + NCVM process | Combining ceramic spraying and non-vacuum metal evaporation (NCVM) technology, with 8 layers of gradient color electroplating process and soft and skin-friendly paint | Brings a textured ceramic touch, enhancing the look and feel of the product |

| 3D special-shaped surface magnetorheological polishing technology | Secondary polishing of the shell that has been processed by CNC, especially the polishing of 3D special-shaped surfaces | Further improve the gloss and feel of the product |

In general, opening a small mobile phone case factory is a business project full of opportunities. As long as entrepreneurs can accurately grasp market demand, design unique products, and formulate reasonable production and operation strategies, they can succeed in this industry. In the future, with the continuous development of the market and the advancement of technology, the mobile phone case industry will usher in more development opportunities and challenges.