6061-T6 vs 6061-T6511 Aluminum: What’s the Difference?

When working with 6061 aluminum, one of the most widely used alloys in engineering and manufacturing, it’s important to understand the differences between its various tempers—especially 6061-T6 and 6061-T6511. While both start with the same base alloy and undergo similar heat treatment processes, the finishing steps and mechanical results differ, which can significantly affect performance in specific applications. In this article, we’ll break down the differences between 6061-T6 and 6061-T6511, and explain when and why you might choose one over the other.

What Is 6061-T6?

6061-T6 is an aluminum alloy that has been:

- Solution heat-treated – heated to a high temperature to dissolve alloying elements into a single-phase solution.

- Quenched – rapidly cooled to lock the elements in place.

- Artificially aged – reheated to a lower temperature to allow the formation of fine precipitates, increasing strength and hardness.

This temper is known for its good strength, corrosion resistance, and general versatility. However, it’s important to note that 6061-T6 is generally limited to sheet or thin stock—typically under 0.25 inches thick.

What Is 6061-T6511?

6061-T6511 also undergoes solution heat treatment and artificial aging, just like T6. However, it includes two additional processing steps:

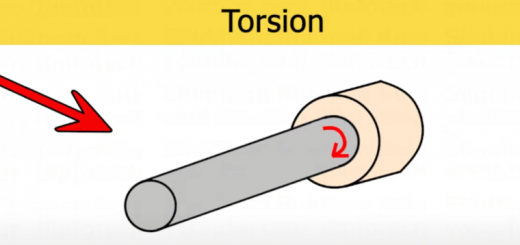

- Stretching – After quenching, the material is stretched slightly (1–3%) to relieve internal stresses caused by rapid cooling.

- Straightening – The extruded product is then straightened to meet tight dimensional tolerances.

This makes 6061-T6511 a stress-relieved and dimensionally stable version of T6, primarily available in extruded bar and rod forms.

Key Differences Between 6061-T6 and 6061-T6511

| Feature | 6061-T6 | 6061-T6511 |

|---|---|---|

| Heat Treatment | Solution heat-treated + artificially aged | Same as T6 |

| Stress Relief | No additional stress relief | Stretched to relieve stress |

| Form | Sheet, thin plate (<0.25”) | Extruded bar, rod |

| Straightening | Not applicable | Yes, for improved tolerance |

| Internal Stress | Higher internal stress | Lower internal stress |

| Dimensional Stability | May warp during machining | More stable; less warping |

| Weldability | Good | Often better due to stress relief |

| Availability | Limited thickness and size | Good for extrusions; limited in wide, thick stock |

Why Choose 6061-T6?

6061-T6 is a solid choice when:

- You’re working with thin sheets or plates under 0.25″ thick.

- You require moderate strength and good formability.

- The part will undergo light machining or forming where internal stresses aren’t a major concern.

- Cost is a priority and dimensional accuracy isn’t overly critical.

Why Choose 6061-T6511?

6061-T6511 is often the better choice when:

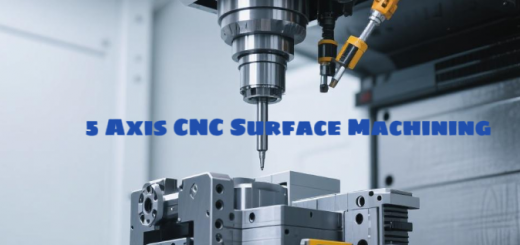

- You’re using extruded bar or rod stock, especially for turned or machined parts.

- The application demands tight dimensional tolerances and stability during machining.

- You anticipate significant material removal or complex geometries during CNC milling.

- You want to minimize distortion or warping.

- Enhanced weldability and reduced risk of stress cracking are important.

Can You Substitute One for the Other?

While T6511 and T6 tempers share the same base heat treatment, they are not always interchangeable. However, 6061-T6511 stock is sometimes dual-certified as T6, which means it meets the requirements of both. This allows T6511 to be used in some applications calling for T6—but not the other way around, as T6 lacks the stress relief of T6511.