How to Use AI Do CNC Programming with CAD Drawings

CNC machining is a complex process that requires precise programming to ensure accurate and efficient production of parts. Traditionally, CNC programmers have relied on manual methods to create G-code programs, which can be time-consuming and prone to errors. However, with the advent of artificial intelligence (AI), it is now possible to automate the G-code generation process using AI-powered tools. Let’s explore how to use AI to create CNC programming language (G-code) from CAD drawings, and test the G-code, as well as challenges and solutions during the process.

Steps of Generating G-Code from CAD Drawings

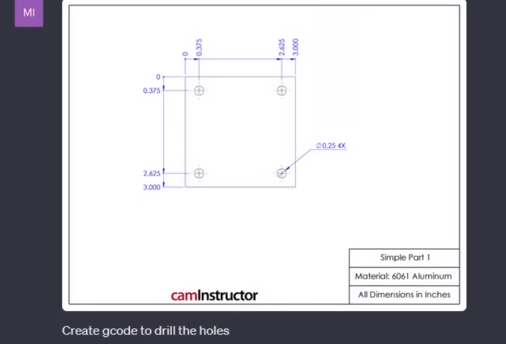

1. Upload the CAD drawing

Upload the CAD drawing of the part you want to create to the AI platform, such as ChatGPT 4. You can attach the image of the part to the chat window.

2. Provide text instructions

Provide a brief text instruction about the print, specifying what you want the AI to do. For example, “Create G-code to drill the holes”.

3. AI analysis and assumptions

The AI will analyze the CAD drawing and make assumptions about the project. It will assume some conditions, such as the machine tool used, the origin, material, cutting speeds, and feeds. If we need to machine a simple part with four holes, the assumptions could be:

The CNC milling machine is being used

The origin is the bottom left corner (although the user may want to change this to the top left corner)

The material is 6061 aluminum

The speeds and feeds will be based on default values

4. AI outputs the G-code

Then AI will generate the G-code program based on its analysis and assumptions. The program may not be optimal, but it should include the correct location of the holes and the necessary drilling instructions. To illustrate the capabilities of AI-powered G-code generation tools, let’s consider an example of generating G-code for a simple part with four holes. The AI tool analyzes the CAD drawing and identifies the four holes to be machined. The tool then generates a G-code program that includes the necessary commands to drill the holes and move the CNC machine to the correct locations.

How AI generates the G-code that spots drills and machines a pocket:

1. AI analyzes the CAD drawing and identifies the features to be machined, including the four holes and the pocket.

2. AI generates the spot drill code, which involves creating a small hole at the location of each hole to be drilled. And determines the correct depth and feed rate for the spot drill operation.

3. AI generates the drill code, which involves drilling the four holes to the correct depth and diameter. The AI determines the correct drill bit size, feed rate, and spindle speed for the drill operation.

4. AI generates the pocket milling code, which involves machining the pocket to the correct shape and size. The AI determines the correct endmill size, feed rate, and spindle speed for the pocket milling operation.

5. AI combines the spot drill, drill, and pocket milling code into a single G-code program. The program includes the necessary G-code commands, such as G01 (linear interpolation) and G04 (dwell), to control the CNC machine’s movements and actions.

6. AI refines the G-code program by adding any necessary commands, such as tool changes, coolant control, and safety checks. The AI also checks the program for errors and inconsistencies.

7. AI outputs the final G-code program, which can be used to control the CNC machine and machine the part.

How to know if the G-code is correct?

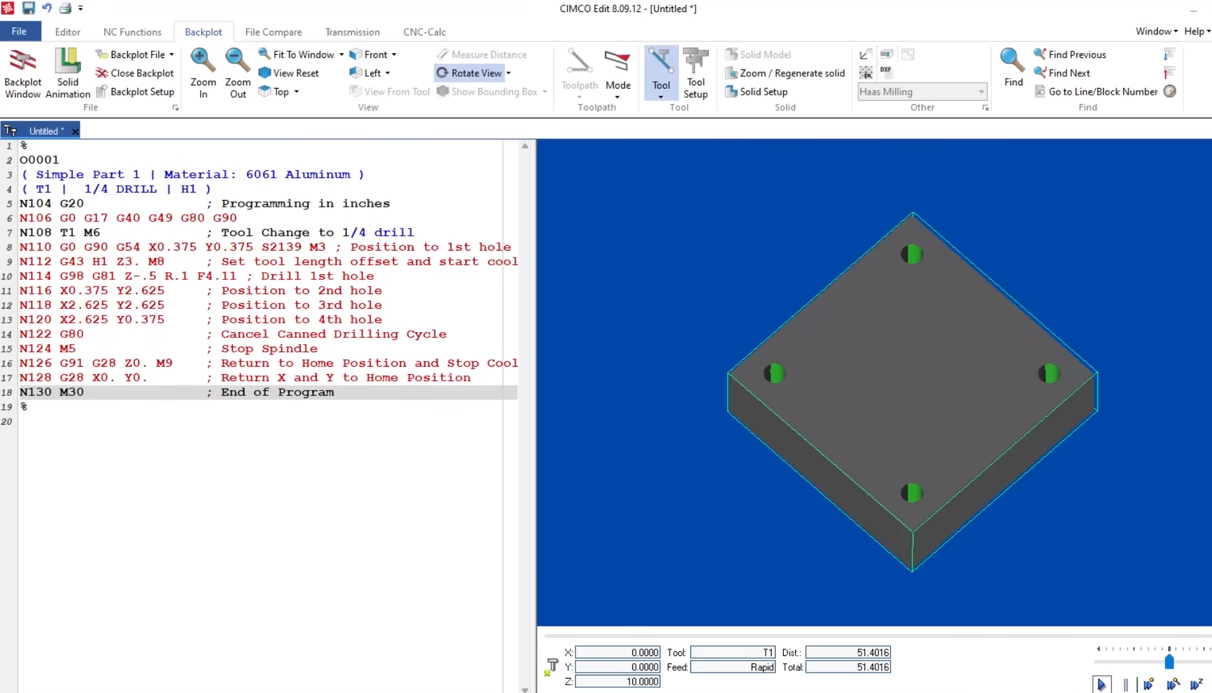

You can review the generated G-code program and refine it as necessary. Check the notes at the bottom of the screen for any precautions or warnings about the code. Copy the generated G-code program and paste it into CIMCO Edit, a program that can backplot and simulate raw G-code. Run the simulation in CIMCO Edit to see how the drill will move and drill the holes. This will give you a visual representation of the G-code program and help you identify any errors or issues.

How to Improve the G-Code from AI?

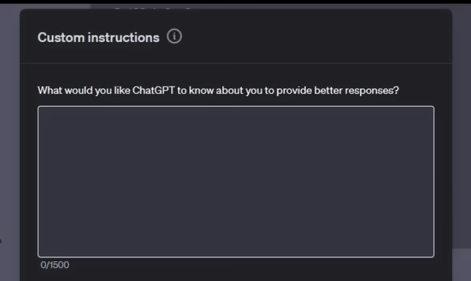

1. Write custom instructions

If you use the GPT 4, in the first box, provide information about yourself to help the AI understand your needs and preferences.

2. Specify response preferences

In the bottom section, specify how you would like the AI to respond.

For example:

If a drawing is in inches, program in inches

Provide a sample snippet of a G-Code program that you’re looking for, including syntax and formatting preferences (e.g. drill calls, CAN cycles, tool changes, coolant codes)

3. Save and start a new chat

Save the custom instructions and start a new chat with the AI.

4. Upload the CAD drawing

Upload the CAD drawing of the part and provide a brief text instruction about the print, specifying what you want the AI to do.

5. AI generates improved G-code

The AI will generate an improved G-code program based on your custom instructions and preferences. The program should include the correct formatting, syntax, and modal CAN cycles.

6. Review and the G-code

Review the generated G-code program with CIMCO Edit again. Check for any errors or issues and make adjustments to the code.

Challenges and Solutions in AI CNC Programming

When we are using AI to generate the G-code for a part with a bolt circle, the AI tool must analyze the CAD drawing and identify the bolt circle pattern, including the location and size of the holes. The challenge or difficult thing is to derive values based on calculations, specifically trigonometric calculations, to determine the correct locations of the holes in a bolt circle. This requires the AI to understand the geometry of the part, apply mathematical formulas, and perform calculations accurately. The bigger challenge here is not only to perform the calculations accurately but also to ensure that the AI understands the context and applies the correct formulas in the correct order.

To solve this challenge, the following measurements can be taken:

– Give the AI more information about the task, such as the specific trigonometric formulas to use, the units of measurement, and the expected output.

– Divide the task into smaller, more manageable parts, and have the AI perform each step individually. This can help to reduce errors and improve accuracy.

– Provide the AI with domain-specific knowledge and expertise in areas like mathematics, geometry, and machining. This can help the AI to better understand the task and apply the correct formulas and calculations.

– Have a human reviewer check the AI’s output and provide feedback on errors or inaccuracies.

Another challenge is dealing with the variability of CNC machines and machining operations, which can make it difficult to generate a G-code program that is universally applicable. To overcome this challenge, it is essential to use AI tools that are designed to work with a variety of CNC machines and machining operations.

AI-powered G-code generation tools have the potential to revolutionize the CNC machining process by automating the G-code generation process and reducing the risk of errors. By providing the AI tool with high-quality CAD drawings and custom instructions, it is possible to generate high-quality G-code programs that are optimized for the specific machining task. With continued improvements and advancements in AI technology, it is likely that AI-powered G-code generation will become an essential tool for CNC machinists and manufacturers.