What is Plasma Cutter – Uses, Pros, Process, Price & Best Plasma Cutters

When it comes to cutting, shaping, or fabricating metal, having the right tool can make all the difference. A plasma cutter is one of the most versatile and efficient tools available for both hobbyists and professionals. In this guide, we’ll break down what a plasma cutter is, the range of tasks it can handle, its advantages and limitations, and highlight the best budget plasma cutters 2026.

What is A Plasma Cutter?

A plasma cutter is a tool that uses a high-velocity jet of ionized gas—known as plasma—to cut through electrically conductive materials such as steel, aluminum, brass, and copper. It works by sending an electric arc through a gas (like compressed air, nitrogen, or argon), which turns the gas into plasma. This plasma reaches extremely high temperatures, melting the metal, while the force of the jet blows the molten material away to create a clean, precise cut.

What Can You Do with Plasma Cutter?

Cutting Metal – Quickly and precisely slice through conductive metals like steel, aluminum, copper, and brass, from thin sheets to thick plates.

Beveling – Create angled edges on metal pieces for welding or fabrication projects.

Gouging and Removing Defects – Remove welds, burn marks, or damaged sections of metal efficiently.

Piercing – Start holes in metal for fast fabrication or design purposes.

Shaping Metal – Cut intricate designs or patterns for automotive parts, artistic projects, or structural components.

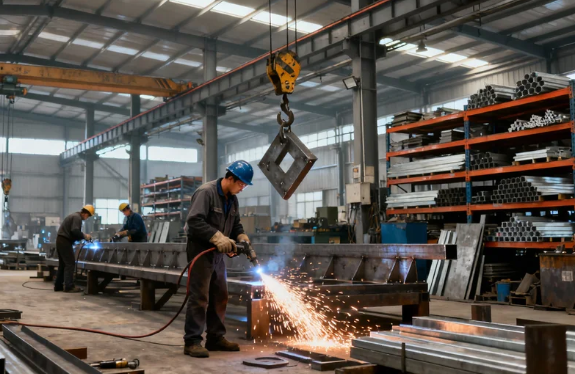

Fabrication and Assembly – Essential for metalwork in automotive repair, industrial manufacturing, shipbuilding, and construction.

Art and Decorative Work – Craft metal sculptures, signs, and decorative panels with precise cuts and intricate details.

Plasma Cutting Process

Plasma conducts electricity, allowing it to form a continuous arc as long as power flows to the electrode and the plasma remains in contact with the metal. To maintain this contact and protect the cut from oxidation, the cutter nozzle includes additional channels that release a steady flow of shielding gas around the cutting area. This gas not only prevents contamination but also helps control the width and stability of the plasma beam.

Advantages of Plasma Cutter

Fast Cutting Speed – Cuts through metal much faster than traditional oxy-acetylene or mechanical saws.

Precision and Accuracy – Produces clean, narrow cuts with minimal heat-affected zones.

Versatility – Can cut a wide range of conductive metals, including steel, stainless steel, aluminum, copper, and brass.

Ability to Cut Thick Metals – Modern plasma cutters can cut several inches thick, depending on power.

Minimal Physical Effort – Requires less manual labor than mechanical cutting methods.

Clean Finish – Reduces the need for grinding or finishing after cutting.

Safe for Small Workshops – No open flame, reducing fire hazards compared to oxy-fuel cutting.

Disadvantages of Plasma Cutter

High Initial Cost – Quality plasma cutters can be expensive, especially industrial-grade models.

Electricity Requirement – Needs a stable power source; some high-amperage units require three-phase power.

Limited to Conductive Metals – Cannot cut non-metallic or non-conductive materials like wood or plastic.

Noise and Fumes – Generates loud noise and metal fumes, requiring safety gear and proper ventilation.

Consumables Wear Out – Electrodes and nozzles degrade over time and need regular replacement.

Skill Required – Precise cutting and complex shapes require some practice and experience.

Plasma Cutter Price

A unit like the Hynade 55A IGBT Plasma Cutter (IGBT, inverter style) can be found for around US$280 (≈ S$400-500 depending on rate) for very light use.

A mid-tier unit like the Riland 100A Plasma Cutting Machine is priced around US$1,800 (≈ S$2,400+) according to listings.

A more professional unit such as the GYS Plasma Cutting Inverter 45 CT is higher in the “serious workshop” bracket (US$1,895 listed).

At the high-end, full industrial machines or CNC tables with plasma systems can run into S$4,000-5,000+ easily, and even higher for top-spec. E.g., the Miller Spectrum 625 X‑Treme is listed around US$4,749 and likely more with shipping/import.

Best Plasma Cutters 2026

1. PrimeWeld CUT50D

Price: $289

Cutting Thickness: Up to 1/2-inch steel

Duty Cycle: 60% @ 50A

Voltage: Dual 120V/240V

Pros:

Powerful for the price, cuts thick metals efficiently.

Dual voltage makes it versatile for home or workshop use.

Long torch connection and easy arc start.

Cons:

Drag torch start can increase consumable wear.

Great value, very capable for medium-duty work; excellent for home users who want solid cutting power without spending a fortune.

2.YESWELDER CUT-55DS

Price: $239

Cutting Thickness: Up to 1/2-inch steel

Duty Cycle: 60% @ 55A

Voltage: 120V (adapter for 240V included)

Pros:

Non-touch pilot arc for cutting painted or rusty metal.

High duty cycle and effective for medium-duty tasks.

Very affordable for its features.

Cons:

Primarily 120V; may struggle in some heavy-duty industrial settings.

One of the cheapest effective plasma cutters with pilot arc technology, excellent for DIY, automotive, and light industrial use.

3.Lotos LTP5000D

Price: $359–$429

Cutting Thickness: Up to 5/8-inch steel

Duty Cycle: 60% @ 50A

Voltage: Dual 120V/240V

Pros:

Pilot arc allows cutting on rusty/painted metal.

Cuts thicker materials than many budget units.

Portable and comes with accessories.

Cons:

Slightly more expensive than YESWELDER or PrimeWeld.

Some user issues with grounding clamp.

Best for users needing thicker cuts and high versatility, still relatively affordable.

4.Super Deal DC Inverter CUT50

Price: $200–$350

Cutting Thickness: Up to 1/2-inch steel

Duty Cycle: 60% @ 50A

Voltage: Dual 110V/220V

Pros:

Very affordable, versatile, and lightweight.

Lift start torch for easy and quieter operation.

Cons:

Moderate cutting speed; not as precise as higher-end models.

Best for tight budgets, functional for home projects and light industrial work.