Internal Thread and External Thread Definition, Types, Differences & Measurement

Threads are an essential element in mechanical engineering and manufacturing, serving as the backbone for fastening, motion transmission, and sealing in countless applications. Understanding the different types of threads, their characteristics, manufacturing processes, and how to select between internal and external threads is crucial for engineers, machinists, and designers to ensure reliable, efficient, and durable mechanical assemblies. This detailed guide expands on the basics, types, standards, and machining techniques of internal and external threads, and provides practical advice on choosing the right thread type for your projects.

What Is an Internal Thread?

An internal thread (female thread) is a helical ridge formed on the inside surface of a cylindrical or conical hole. It is designed to mate precisely with an external thread to form a secure mechanical joint. Internal threads are commonly found inside nuts, threaded holes in machine parts, pipe fittings, and bottle caps. The thread profile is typically cut or formed by tapping or thread milling, requiring precise control of dimensions like pitch, major diameter, and minor diameter.

Internal threads provide excellent sealing capability due to the close engagement with external threads, making them ideal for applications involving fluids or gases, such as plumbing and hydraulic systems. Their geometry also allows for stable fixation under tensile and shear forces. However, internal threads are generally weaker than external threads because the hole walls supporting the threads have less material thickness.

What Is an External Thread?

An external thread(male thread) is a helical ridge formed on the outside surface of a cylindrical or conical part, such as bolts, screws, studs, or threaded rods. This protruding ridge engages with an internal thread to establish a mechanical connection. External threads are designed to bear high loads and provide mechanical strength and durability. Their geometry allows for efficient force transmission and ease of installation or removal.

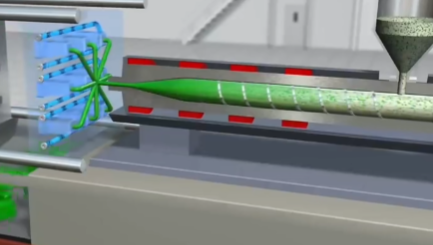

External threads are produced by machining methods such as turning, thread rolling, or grinding. Thread rolling, in particular, improves thread strength by cold-working the surface and aligning grain flow. While external threads generally offer higher strength and load capacity, they typically provide less sealing capability than internal threads and often require additional sealing elements for leak-proof applications.

Common Types of Threads in Mechanical Engineering

Thread types have evolved over time to meet different functional and manufacturing requirements. Each thread profile has unique characteristics affecting strength, friction, sealing, ease of manufacture, and application suitability.

Triangular (V-Shaped) Threads

The most widely used thread profile, characterized by a 60° angle in metric and Unified standards or 55° in Whitworth threads. V-threads are common in bolts, screws, and nuts due to their good balance of strength and ease of manufacture. They are made using standard cutting tools like taps and dies.

Square Threads

Square threads have a square cross-section, offering the highest efficiency for power transmission due to minimal friction. They are used in heavy-duty applications such as jackscrews, presses, and lead screws. Their manufacturing complexity and lower strength compared to V-threads limit their use.

Acme Threads

A modified square thread with a 29° flank angle, easier to machine and stronger than square threads. Acme threads are used in machinery like bench vises, brass valves, and lead screws. They provide a smooth sliding action with minimal backlash.

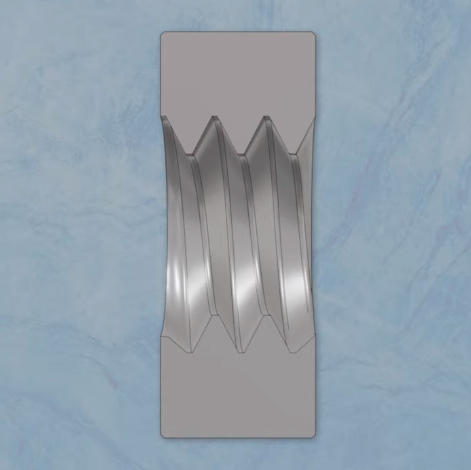

Buttress Threads

Featuring one face perpendicular and the other sloped, buttress threads combine the strength of V-threads with the low friction of square threads. They are designed to withstand heavy loads in one direction, common in applications like hydraulic presses and airplane propeller hubs.

Knuckle Threads

Rounded crests and roots make knuckle threads resistant to damage and debris accumulation, ideal for harsh environments. They are used in railroad couplings, glass bottle necks, and large electrical insulators.

Worm Threads

Similar to Acme threads but deeper, worm threads have a 29° angle and are used in worm gear assemblies to transmit motion at right angles with high reduction ratios.

Single and Multi-Start Threads

Single-start threads have one continuous helical ridge, while multi-start threads have two or more, allowing faster linear travel per rotation. Multi-start threads are used in applications requiring rapid assembly or movement.

Right-Hand Threads

The most common thread direction, tightening clockwise.

Left-Hand Threads

Tighten counterclockwise, used where rotation might loosen right-hand threads, such as in some machinery or rotating parts.

Differences Between Internal Threads and External Threads

| Feature | Internal Threads (Female) | External Threads (Male) |

|---|---|---|

| Location | Inside a hole or bore | Outside cylindrical or conical surfaces |

| Geometry | Thread groove inside the hole | Thread ridge protruding from the surface |

| Strength | Lower strength due to material removal | Higher strength due to more material and shape |

| Sealing | Better sealing capability with a matched external thread | Usually requires additional sealing methods |

| Application | Nuts, pipe fittings, threaded holes | Bolts, screws, studs, shafts |

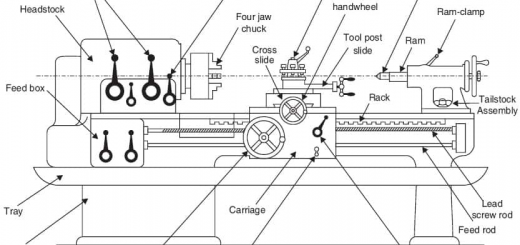

| Manufacturing Methods | Tapping, thread milling | Turning, thread rolling, grinding |

| Load Direction | Often designed to hold under tensile loads | Designed for tensile, shear, and torsional loads |

| Repair | More difficult to repair if damaged | Easier to replace or re-cut |

Internal vs External Thread: Which One to Choose?

Choosing between internal and external threads depends on several factors:

- Application Requirements: Internal threads are ideal for receiving fasteners or providing sealing inside components, such as nuts or pipe fittings. External threads are needed on parts like bolts, screws, or shafts that need to be inserted into internal threads.

- Load and Strength: External threads generally bear higher loads and provide greater strength due to more material volume. Internal threads offer better sealing and fixation but are relatively weaker.

- Material and Environment: Material properties and environmental conditions affect thread choice. For example, internal threads in soft materials may wear out faster, while external threads exposed to harsh conditions require corrosion-resistant coatings.

- Ease of Manufacturing and Repair: External threads are easier to inspect and repair, or replace. Internal threads require precision tapping and can be harder to fix if damaged.

- Sealing Needs: Internal threads combined with matching external threads provide good sealing, which is critical in fluid or gas systems.

Thread Dimensions and Parameters Explained

- Major Diameter: The largest diameter of the thread, measured at the crest.

- Minor Diameter: The smallest diameter, at the root of the thread.

- Pitch Diameter: The diameter at which the thread thickness equals the space between threads; critical for thread fit.

- Pitch: The distance between two adjacent thread crests along the axis.

- Lead: The distance a screw advances axially in one full turn; equals pitch for single-start threads, multiple of pitch for multi-start.

- Thread Angle: The angle between the flanks of the thread, typically 60° for metric and Unified, 55° for Whitworth.

- Thread Lead Angle: Angle of the thread helix relative to a plane perpendicular to the axis.

- Class of Fit: Defines tolerances for mating threads (e.g., 1A/1B loose fit to 3A/3B tight fit).

Thread Standards

- Unified Thread Standard (UTS): Used mainly in the US, Canada, and UK; classes 1A/1B (loose), 2A/2B (standard), 3A/3B (tight).

- ISO Metric Threads: International standard using millimeters (e.g., M8x1.25).

- British Standard Whitworth (BSW): Imperial thread with 55° angle, round crests and roots.

- British Standard Fine (BSF): Similar to BSW but finer pitch for vibration resistance.

- National Pipe Thread (NPT): Tapered thread for sealing pipes.

- Buttress Thread: Specialized for unidirectional load.

- Seller Threads: American National threads with flat crests and roots.

How to Measure Internal and External Thread Sizes?

Accurately measuring thread sizes is a critical skill in manufacturing, maintenance, and assembly. Whether you are working with bolts, nuts, screws, or threaded components, knowing how to measure thread dimensions ensures that mating parts fit perfectly. Incorrect measurements can lead to mismatched parts, weak joints, or even mechanical failure. Here we break down the process of measuring both external (male) and internal (female) threads, explain the terminology, and introduce useful tools and techniques for precise measurement.

A screw thread is a helical ridge wrapped around a cylinder or cone, designed to mate with a complementary thread. This interlocking spiral shape allows parts to be fastened securely. The thread comprises ridges (called crests) and valleys (roots), where the crest of one thread fits into the valley of the matching thread, preventing unintended separation. Threads are characterized by three critical dimensions: the diameter, the spacing between threads, and the length over which threads extend. These dimensions are standardized to ensure that one threaded part fits perfectly with its counterpart.

Imperial vs Metric Threads: Units and Terminology

Thread measurements use two primary systems: Imperial and Metric.

- Imperial Threads use inches for diameter and measure thread spacing by Threads Per Inch (TPI). This is commonly used in the United States and regions influenced.

- Metric Threads use millimeters for diameter and measure thread spacing by pitch – the distance in millimeters between adjacent threads. The metric is the global standard and widely used outside the US.

The difference between TPI and pitch is important. TPI counts how many threads fit in one inch, whereas pitch measures the distance from crest to crest in millimeters. They are mathematically inverse to one another but are used exclusively in their respective systems.

Step 1: Identify the Thread Type

The first step is to determine if you are measuring an external thread or an internal thread.

- External threads (male) are on the outside of bolts, screws, or studs. These are easier to measure since the ridges are visible.

- Internal threads (female) are inside nuts, tapped holes, or fittings. Measuring these is more difficult due to restricted access.

If you find the thread diameter varies along its length, it is likely a tapered pipe thread, which requires special charts for measurement.

Step 2: Measure the Thread Diameter

For external threads, use a ruler or caliper to measure the major diameter — the distance from crest to crest across the thread’s widest point. Place the fastener parallel to the measuring tool to avoid errors. For internal threads, measure the minor diameter — the smallest diameter inside the threaded hole. This is usually done with a caliper, carefully centering it inside the hole to avoid misalignment. Using a digital or vernier caliper provides more accuracy than a ruler, especially on small threads.

Step 3: Determine Thread Spacing — Pitch or Threads Per Inch (TPI)

- For Imperial Threads (TPI): Place the fastener’s head at the zero mark on a ruler. Count the thread crests within one inch. If the threaded length is less than one inch, count the number of threads within the available length and multiply to estimate TPI. For example, if you count 4 threads in 0.5 inches, the TPI is 8.

- For Metric Threads (Pitch): Align the fastener with the ruler and measure the distance between two adjacent thread crests or valleys in millimeters. Pitch is often very small. To increase accuracy, count multiple threads (e.g., 10 threads), measure the total length, and divide by the number of threads. For instance, 10 threads over 25 mm means a pitch of 2.5 mm.

Step 4: Cross-Reference With Thread Charts

Once the diameter and pitch or TPI are known, consult standard thread charts to identify the exact thread size. Use SAE or Unified thread charts for imperial measurements and ISO metric charts for metric threads. If the measurements do not match any standard sizes, consider:

- The thread might be worn, reducing the diameter.

- The thread could be a pipe thread or a special form.

- You might need to try the next closest standard size.

Always verify with physical thread gauges or sample fasteners if possible.

More Tools and Methods for Thread Measurement

- Thread Pitch Gauge: A thread pitch gauge is one of the simplest and most effective tools for measuring thread spacing. It consists of multiple thin leaves with teeth that match various thread pitches or TPI values. To use, press the gauge against the thread and find the leaf that fits perfectly without gaps.

- This tool works for both internal and external threads and is inexpensive, making it ideal for quick identification.

- Calipers: Calipers, especially digital or vernier types, allow precise measurement of thread diameters. For external threads, measure across the crests. For internal threads, carefully measure the smallest diameter inside the bore. Avoid tilting the caliper jaws to prevent inaccurate readings.

- Combined Use of Caliper and Pitch Gauge: Using both a caliper and a thread pitch gauge together is a fast and reliable way to identify thread size. The caliper measures diameter, and the pitch gauge identifies thread spacing. Then, you can easily match these parameters to a standard size chart.

- Nut and Bolt Gauges: These specialty gauges include sets of threaded samples or holes that represent common thread sizes. By trying to thread the fastener onto the gauge or vice versa, you can quickly identify which size fits best. Nut and bolt gauges come in flat card styles, wall-mounted boards, or linked kits. They are very convenient but must be used carefully to avoid damaging threads by forcing an incorrect match.