Thrust Bearing Definition, Purposes, Types, Uses, Size Chart

Bearings are fundamental components in countless machines, allowing for smooth and reliable rotation or movement while reducing friction. Among the various types of bearings, thrust bearings are designed to handle forces that act along the axis of a shaft, ensuring stability and efficiency when axial loads are present. This guide will provide a detailed look at what thrust bearings are, why they are used, their main types and applications, as well as how to determine their sizes and reference a typical size chart.

What is a thrust bearing?

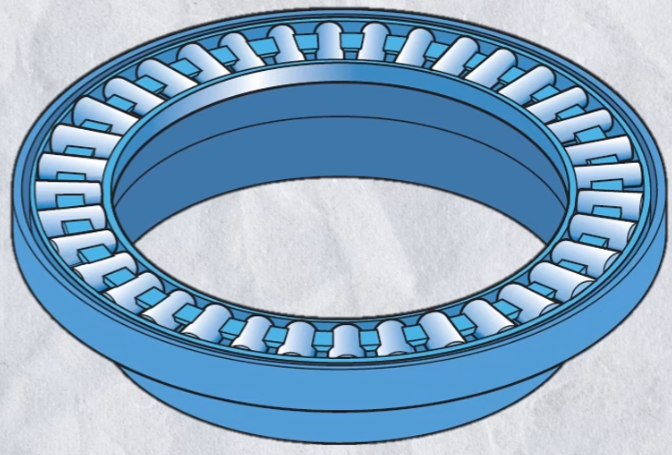

A thrust bearing is a type of bearing specifically designed to support loads that are applied parallel to the shaft, which is referred to as an axial or thrust load. Unlike radial bearings that handle forces perpendicular to the shaft, thrust bearings are intended to maintain the position of rotating components when subjected to forces along the axis of rotation. The construction of thrust bearings typically involves rolling elements such as balls, rollers, or needles placed between two separate plates, which allows for relative movement while supporting axial loads. The design does not usually trap the rolling elements inside the race, which makes thrust bearings resemble a sandwich or burger with a cage and two plates on each side.

Purpose of Thrust Bearing

The primary function of a thrust bearing is to support and constrain components under axial loading conditions. In scenarios where a load acts along the centerline of a shaft or rotating part, thrust bearings ensure that the moving element is held securely while still allowing smooth rotation with minimal friction. For example, in a bicycle’s handle assembly, the axial force from the rider and bicycle body is transmitted downwards, and the bearing must keep the handle and frame together, allowing rotation without excessive wear. If the load is applied axially, the inner race of the bearing moves downward and the outer race moves upward, and the rolling elements—such as balls—must effectively hold these races together. This makes thrust bearings essential in applications where components must remain constrained axially yet free to rotate.

Thrust Bearing Types & Uses

Thrust bearings come in several main designs, each suited for specific load conditions and operational requirements:

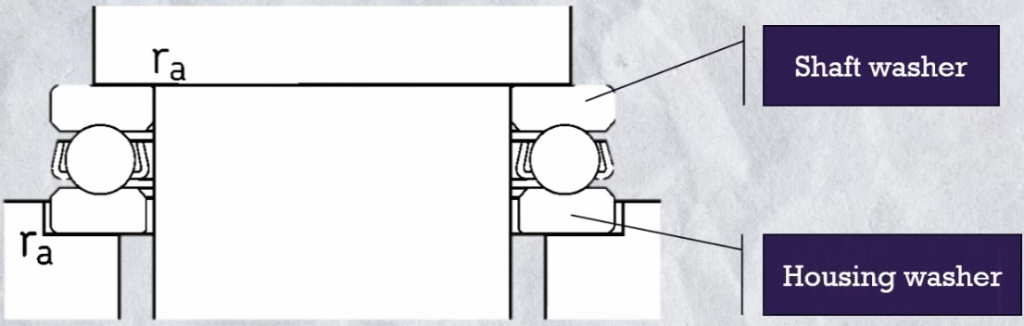

Single Direction Thrust Ball Bearing (51 series)

This design features two plates, one for the shaft and one for the housing. and is suitable for loads applied in only one axial direction. The shaft washer fits tightly on the shaft, while the housing washer has a larger bore to allow for rotation. These are commonly used in situations where axial load is present only from one side, such as the bottom support in a bicycle handle.

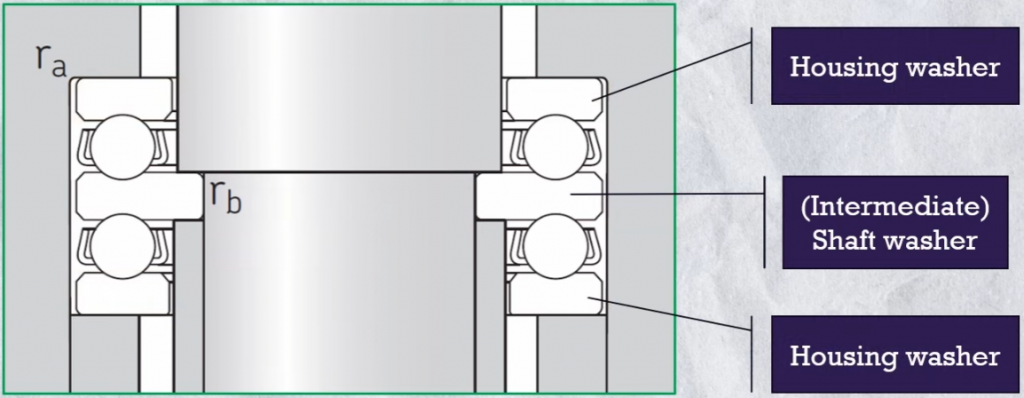

Double Direction Thrust Ball Bearing:

With two housing washers and a central shaft washer, this bearing can support axial loads from both directions. This design is useful in assemblies where forces may alternate, such as when a bicycle handle experiences both upward and downward forces due to uneven surfaces.

Spherical Housing Washer Variants:

For applications where initial misalignment may occur, there are thrust bearings available with a spherical housing washer to accommodate these small angular deviations.

Cylindrical Roller Thrust Bearing:

When heavier axial loads are expected, ball elements are replaced with rollers, which provide a larger contact area and higher load capacity. These bearings are available in both single and double direction configurations.

Needle Thrust Bearing:

In cases where space is restricted, such as compact assemblies, cylindrical rollers are replaced with needle rollers. These bearings come in either a needle roller and cage assembly or with a centering flange design.

Thrust bearings are used in numerous applications, including automotive gearboxes, machine tool spindles, marine propeller shafts, and rotating equipment where axial forces are a concern. In some cases, deep groove ball bearings can handle a degree of axial load, but the amount is limited. For example, deep groove ball bearings are suitable for light axial loads, but their axial load capacity should be less than half of their basic dynamic load rating (C) for most series, and only a quarter for lighter series (starting with 60 or 602). Cylindrical roller bearings, on the other hand, are not ideal for axial loads due to increased friction and limited speed capability.

Thrust Bearing Dimensions (Calculation & Size Chart)

Selecting the correct thrust bearing involves considering the shaft diameter, housing bore, bearing height, and the required axial load capacity. The dimensions must match the specific requirements of the assembly to ensure proper fit and function.

For standard bearings, manufacturers provide catalogs with detailed size tables. For example, a typical thrust ball bearing size chart might include:

| Bearing Number | Shaft Diameter (mm) | Outer Diameter (mm) | Height (mm) | Dynamic Load Rating (kN) |

|---|---|---|---|---|

| 51100 | 10 | 24 | 9 | 19.6 |

| 51101 | 12 | 26 | 9 | 22.4 |

| 51102 | 15 | 28 | 9 | 23.2 |

| 51103 | 17 | 30 | 9 | 23.6 |

| 51104 | 20 | 35 | 10 | 28.1 |

| 51105 | 25 | 42 | 11 | 34.5 |

To calculate size, start by determining the shaft size and the maximum expected axial load. Then, consult the bearing manufacturer’s catalog to find a bearing whose dimensions and load rating meet or exceed your requirements. Always consider peak loads and service conditions, as excessive or repeated overloading can reduce bearing life. In special cases, needle or roller type thrust bearings may be selected for higher capacities or limited space.