Steel Hardness Measurement/Scales, HRC Calculation/Chart, Hardening Processes

As a mechanical engineer, especially in design, understanding the steel hardening process is crucial. It is the responsibility of the designer to specify the correct hardening method and HRC value for steel components, particularly for tooling and sliding parts subjected to cyclic loads.

What Is Hardness?

Hardness is defined as the resistance of a material to localized plastic deformation. This means the ability of steel to withstand forces without permanent indentation, scratching, or penetration. Harder materials offer higher resistance to plastic deformation, which correlates with higher yield strength.

For example:

- Plain carbon steel: 250–550 MPa yield strength

- Pure aluminum: 35–50 MPa yield strength

- Titanium: 800–900 MPa yield strength

Hardness is often estimated in terms of yield strength, but the true behavior of materials under force is complex. Therefore, several standardized methods are used to measure hardness.

The Importance of Hardness in Steel Components

Mechanical engineers, particularly design engineers, must specify both the appropriate hardening method and the target hardness value (often given in HRC) for steel parts. This is especially important for:

- Tooling components: Punching, bending, flattening, clinching, riveting, marking, and cutting tools (like cutters and drills) are subjected to cyclic loads and need to maintain their shape and sharpness.

- Sliding components: Items such as guide rails, linear motion shafts, cams and followers, bushes, bearings, locating pins.

- Gears, sprockets, splines, molds, and dies: These experience frequent loading and require adequate hardening to preserve geometry and edge integrity even under heavy or sudden forces.

Ensuring components are hardened to the right degree extends tool life and maintains reliable function.

Defining Hardness and Measurement Methods

Hardness measures the resistance to localized plastic deformation such as scratching, penetration, or indentation. More hardness implies greater resistance to plastic deformation, starting after the yield strength point. For example, plain carbon steel yield strength ranges between 250 to 550 MPa, pure aluminum between 35 to 50 MPa, and titanium between 800 to 900 MPa, indicating that steel is harder than pure aluminum, and titanium alloys are harder than steel. Hardness can be measured in three main ways:

Scratch Hardness: Indicates resistance to scratching. Measured using the Mohs scale (1 to 10), commonly applied in coating and surface treatment industries.

Indentation Hardness: Measures resistance to penetration by a sharp object under a known force. Used for general engineering purposes and divided into macro, micro, and nano indentation, with macro being most relevant for engineers.

Rebound Hardness: Indicates the material’s ability to bounce, measured with devices like the Scleroscope. Related to material elasticity.

Indentation Hardness Scales and Their Application

Macro-indentation hardness testing uses scales such as Rockwell, Vickers, and Brinell. Different regions and applications prefer different scales:

– Rockwell (HRB, HRC): Popular in the USA and India.

– Vickers (HV): Common in Japan and Europe, highly accurate for thin materials and small samples.

– Brinell (BHN, HBW): Used for materials with coarse structure such as cast parts, correlated with ultimate tensile strength.

Popular Indentation Hardness Scales

| Scale | Indicator | Load | Material Type |

|---|---|---|---|

| Rockwell HRB | Ball | 100 kgf | Softer materials (aluminum, brass) |

| Rockwell HRC | Conical | 150 kgf | Hard materials (steel, hard cast iron) |

| Vickers (HV) | Diamond Pyramid | Variable | All materials, thin/small samples |

| Brinell (BHN) | Ball (Tungsten Carbide) | Variable | Coarse structures (cast iron) |

HRC Calculation and Example

The Rockwell hardness (HRC) is calculated as follows:HRC = N - (h × S)

Where N and S are scale-specific constants, and h is the penetration depth in mm.

Example: For a steel piece with a penetration depth of 0.1 mm (100 micron) on the C scale:HRC = 100 - (500 × 0.1) = 50 HRC

Initial Hardness of Steel Grades and Influencing Factors

Pure iron (Fe) has low hardness (0–5 HRC), so carbon (up to 2% by weight) is added to form steel. Hardness increases with carbon content, but too much carbon (>2%) produces brittle cast iron. Additional alloying elements (chromium, manganese, vanadium, molybdenum) further enhance properties like toughness and wear resistance.

Approximate Hardness by Carbon Content

| Steel Type | Carbon (%) | Typical HRC |

|---|---|---|

| Low Carbon | 0.05–0.25 | 10–15 |

| Medium Carbon | 0.3–0.6 | 15–25 |

| High Carbon | 0.6–1.4 | 20–30 |

Cold working (rolling, forging) increases hardness due to plastic deformation and dislocation density. Hot working results in softer steel. Typical raw steel hardness ranges from 20–40 HRC, sufficient for general machine parts but not for tooling or sliding components.

Required Hardness Levels for Different Applications

Recommended HRC Values for Steel Components

| Component | Hardness (HRC) |

|---|---|

| Cutting Tools (Cutters, Drills) | 60–65 |

| Punching Tools | 58–65 |

| Marking Tools | 55–60 |

| Bending Tools | 50–55 |

| Light Load Tools (Flaring, Clinching, Riveting) | 45–50 |

| Sliding Rails | 50–60 |

| LM Shaft | 58–62 |

| Bearings | 58–65 |

| Bushes | 40–50 |

| Gears, Splines | 58–62 |

| Sprocket | 55–60 |

| Cam Follower | 55–62 |

| Plastic Molds | 48–56 |

| Die Casting Mold | 60–64 |

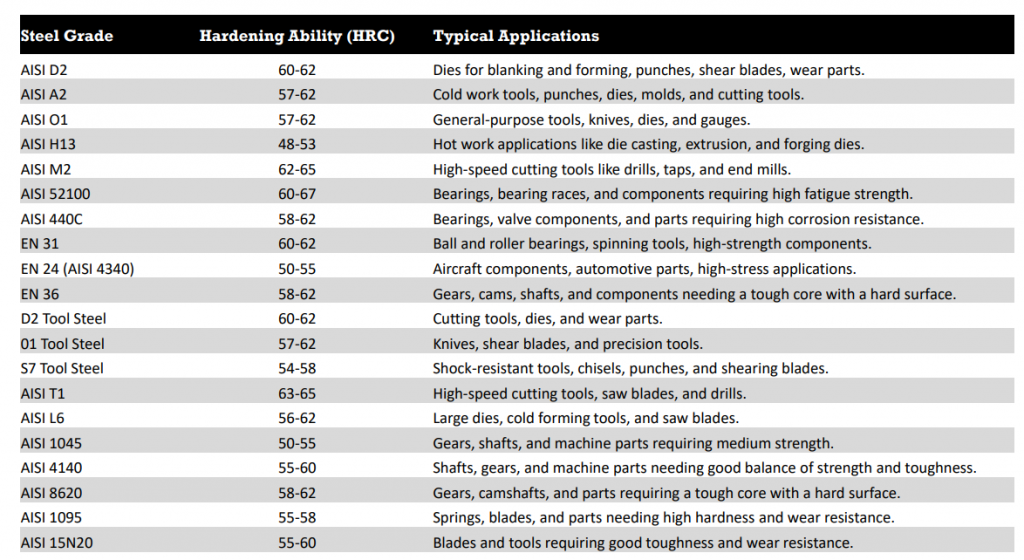

Steel HRC Chart for Different Grades

Steel Hardening Processes and Their Selection

Steel should not be hardened before all machining is complete, as hardness above 40 HRC makes machining difficult and reduces tooling life. The primary hardening methods are quenching and tempering. Quenching involves heating steel above its critical temperature (750–950°C), holding, then rapidly cooling in water, oil, or air to achieve high hardness. Tempering follows quenching to reduce brittleness by reheating to 150–650°C and cooling moderately.

Steel Microstructure and Hardening Chemistry

Steel is a polycrystalline solid composed of grains. At room temperature, untreated steel consists mainly of ferrite (soft, BCC structure) and cementite (hard, brittle, Fe3C). To increase hardness, the ferrite phase must be altered by heating to the austenite phase (FCC structure), which traps more carbon atoms. Rapid cooling (quenching) transforms FCC grains into martensite (BCT structure), resulting in high hardness. Not all grains transform, and the fraction depends on cooling rate and carbon content. Fast cooling and higher carbon content increase martensite formation.

Choosing the Right Steel Grade for Hardening

Hardness is not the only requirement; tooling and sliding components also need wear resistance and toughness. Alloy steels and tool steels (e.g., D2, A2, HSS, EN31) provide high hardenability, wear resistance, and edge retention.

Example High Hardness Steel Grades

| Steel Grade | Max HRC | Typical Use |

|---|---|---|

| D2, A2 | 60–62 | Cutting, die, punch tools |

| Tungsten Carbide, Cobalt Carbide | 70–90 | High-speed, abrasive cutting |

| HSS (M2) | 62–64 | Drill bits, saw blades |

| EN31 | 60–64 | Bearings, rollers |

| EN24, EN19 | 54–58 | Wear parts |

Classification of Hardening Processes

Full Hardening: Hardens the entire component cross-section, achieved through quenching and tempering. Suited for small components (drills, cutters), not recommended for large or thick parts due to heating uniformity challenges.

Full Hardening Methods

| Method | Cooling Medium | Key Features |

|---|---|---|

| Water Quenching | Water | Fast cooling, high hardness (60–65 HRC), higher risk of cracking/distortion |

| Oil Quenching | Oil | Moderate cooling, balanced hardness and toughness, fire hazard risk |

| Air Quenching | Air | Slow cooling, minimal distortion, for thin/complex parts |

| Polymer Quenching | Polymer solution | Intermediate cooling rate |

| Salt Bath Quenching | Molten Salt | Uniform, controlled cooling, for precision components |

Case Hardening (Surface Hardening)

Hardens only the outer surface, leaving the core softer and ductile. Used where only surface wear resistance is needed, as in LM shafts and bushes.

Case Hardening Techniques

| Method | Description | Applications |

|---|---|---|

| Flame Hardening | Surface heated by flame, then quenched to form martensite layer | Large gears, tracks, crane wheels |

| Induction Hardening | Heated by induction, then quenched | Shafts, axles, gears, bearing races |

| Carburizing | Heated in carbon-rich environment, carbon diffuses into surface | Automotive gears, camshafts, crankshafts |

| Nitriding | Heated in nitrogen-rich environment, forms hard nitrides | Engine parts, aircraft, high-performance tools |

| Carbonitriding | Exposed to carbon and nitrogen gases | Screws, fasteners, small gears |

| Cryogenic Hardening | Cooled to extremely low temperature after heat treatment | Engine parts, gears, bearings, sports tools |

Age hardening is primarily used for aluminum alloys, not steel.