PA11 vs PA12 – Nylon 11 and Nylon 12 Properties, Differences and Applications

Understanding the differences between PA11 and PA12 is important if you’re curious about materials used in 3D printing and manufacturing. Both are types of nylon used to make everything from car parts to sports gear and medical devices. Choosing the right one can make a big difference in how strong, flexible, or durable your 3D printed parts are. In this guide, we’ll dive deep into what PA11 and PA12 are, their unique properties, differences, and which one you might want to pick for your own projects.

What Is PA11?

Polyamide 11, also known as PA11 or nylon 11, is a special type of plastic made from natural, renewable resources. Unlike many plastics that come from oil, PA11 is made from castor plants, which makes it more environmentally friendly. The process involves turning castor oil into a chemical called 11-amino undecanoic acid, which is then polymerized (joined together in long chains) to form PA11.

PA11 is famous for its strong and flexible nature. It can resist chemicals like oils, fuels, and solvents, making it useful in tough environments. It also handles heat well, standing up to temperatures around 190°C before melting. PA11’s flexibility means it can bend and stretch without breaking, which is great for parts that need to absorb shocks or be flexible like hinges or clips.

Because PA11 comes from plants, it has a lower environmental impact compared to many other plastics. It absorbs only a small amount of water, which helps parts keep their size and shape even in humid conditions. However, PA11 can be expensive and needs special care during processing to work well.

Is polyamide 11 the same as nylon 11?

Yes. Polyamide 11 and nylon 11 are simply two names for the same material. “Polyamide” is the technical term, while “nylon” is the everyday name people use.

What Is PA12?

Polyamide 12 (PA12), or nylon 12, is another kind of nylon used widely in manufacturing and 3D printing. Unlike PA11, PA12 is usually made from petroleum (oil), though there are bio-based versions too. It is a semi-crystalline thermoplastic, which means it has a mix of ordered and disordered parts in its structure, helping it stay strong and stable.

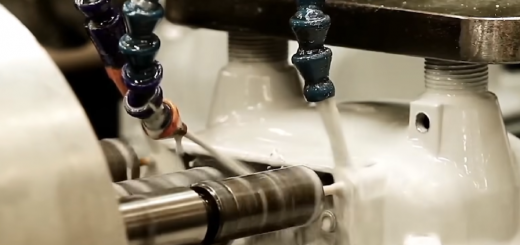

PA12 melts at a slightly lower temperature than PA11, around 176°C. It is known for its excellent durability, especially when it comes to resisting wear and tear. It handles oils, fuels, hydraulic fluids, and solvents well. PA12 is less flexible than PA11 but offers better dimensional stability, meaning it holds its shape better under heat or mechanical stress.

This makes PA12 ideal for parts like gears, tubes, or mechanical components that must keep precise shapes and withstand harsh conditions. PA12 also absorbs very little water, about 0.5%, which helps parts maintain accuracy in humid or wet environments.

Is PA12 the same as Nylon 12?

Yes. PA12 and nylon 12 are just different names for the same material.

Characteristics of PA11

- Bio-based: PA11 is made entirely from renewable resources, specifically castor plant oil. This makes it one of the rare bio-based thermoplastics available on the market. Because it is derived from plants rather than petroleum, PA11 has a significantly lower environmental impact, contributing to sustainability and reducing reliance on fossil fuels.

- Chemical Resistance: PA11 exhibits excellent resistance to a wide range of chemicals, including greases, fuels, solvents, and salt solutions. This makes it highly suitable for applications where the parts are exposed to harsh chemical environments, such as automotive fuel lines or industrial components.

- Impact Resistance: One of PA11’s standout features is its exceptional impact resistance. It remains flexible and strong even at very low temperatures, where many plastics become brittle. This high elongation at break allows PA11 parts to absorb shocks and stresses without cracking or breaking.

- Water Absorption: PA11 absorbs very little water compared to many other polyamides. Its low water absorption helps maintain the dimensional stability of parts, ensuring they hold their shape and size even in humid or wet conditions. This is critical for precision components.

- Thermal and UV Resistance: PA11 offers good resistance to heat and ultraviolet (UV) light. It can withstand prolonged exposure to sunlight and weather without degrading quickly, making it a good choice for outdoor applications or parts exposed to sunlight or heat.

- Flexibility: PA11 is highly flexible and elastic, capable of withstanding bending, twisting, and repeated mechanical stress without permanent deformation. This makes it ideal for applications like living hinges, clips, or flexible joints that need to endure continual movement.

- Wear Resistance: The material is resistant to abrasion, aging, and stress cracking. PA11 parts can endure long-term wear and tear without significant degradation, which is particularly valuable in dynamic or mechanically loaded components.

- Noise and Vibration Damping: PA11 naturally absorbs vibrations and reduces noise, making it useful in applications where noise reduction and vibration damping are important, such as automotive parts and machinery housings.

- Fatigue Resistance: PA11 performs excellently under cyclic loading conditions, meaning it can withstand repeated stress and bending without losing structural integrity. This fatigue resistance is crucial in parts subjected to constant motion or vibration.

- Electrical Properties: The electrical performance of PA11 depends on its moisture content. Since polyamides absorb moisture, drying the material properly before processing is essential to maintain consistent electrical insulation properties and avoid processing defects.

- Limitations: Despite its many strengths, PA11 is relatively expensive compared to many other polymers. It is sensitive to boiling water and strong acids, which can degrade the material. Also, careful drying before processing is necessary to avoid issues during 3D printing or molding.

Characteristics of PA12

- Semi-crystalline Thermoplastic: PA12 is a semi-crystalline polymer, which provides it with excellent strength and dimensional stability. The semi-crystalline structure means it has both ordered and amorphous regions, helping it maintain shape under mechanical stress and temperature variations.

- Chemical Resistance: PA12 resists a broad spectrum of chemicals, including oils, fuels, hydraulic fluids, grease, solvents, and salt solutions. This chemical durability makes PA12 a preferred choice for automotive and industrial applications where exposure to harsh fluids is common.

- Impact Resistance: While PA12 offers good impact resistance, it is generally slightly lower than that of PA11. It still performs well in absorbing shocks and mechanical stress but is a bit less flexible and ductile.

- Water Absorption: PA12 has very low water absorption, around 0.5%, which is among the lowest of commercial polyamides. This minimal moisture uptake leads to excellent dimensional stability, making PA12 ideal for precision parts that must maintain tight tolerances.

- Thermal Resistance: PA12 exhibits excellent resistance to temperature fluctuations and can maintain its mechanical properties under both elevated and sub-zero temperatures. This makes it suitable for outdoor applications and parts exposed to extreme temperature cycles.

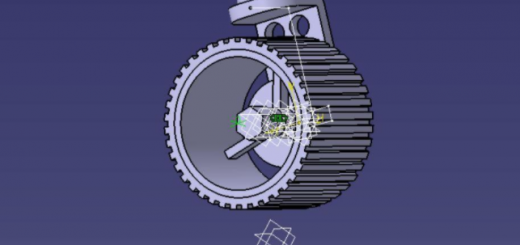

- Abrasion Resistance: One of PA12’s strongest features is its outstanding resistance to abrasion. It can withstand continuous friction and wear, which is why it is often used for moving parts like gears, hinges, and bearings.

- Surface Finish:

Parts made from PA12 typically have a slightly rougher surface finish compared to PA11. However, transparent grades of PA12 are available, which allow for more design flexibility, especially in applications where visual inspection or aesthetics are important. - Noise and Vibration Damping:

PA12 also offers good noise and vibration damping properties. Its ability to reduce vibrations and absorb sound makes it suitable for machinery components and automotive parts where noise reduction is desired. - Fatigue Resistance:

PA12 performs well under repetitive cyclic loading, meaning it can tolerate repeated bending and stress cycles without failure. This fatigue resistance makes it reliable for dynamic applications. - Electrical Properties:

Like PA11, the electrical properties of PA12 depend heavily on moisture content. Proper drying before processing is essential to achieve consistent electrical insulation and to avoid printing or molding defects. - Limitations: PA12 tends to be more expensive than many other polyamides. Its UV resistance is lower than that of PA11, which can limit its use in long-term outdoor applications without additional UV stabilization. Also, like most polyamides, PA12 requires proper drying before processing to avoid moisture-related issues.

| Property | Unit | PA11 (Nylon 11) | PA12 (Nylon 12) |

|---|---|---|---|

| Thermal Properties | |||

| Heat Deflection Temperature | °C | 110 | 97 |

| Glass Transition Temperature | °C | 46 | 75.2 |

| Vicat Softening Temperature | °C | 140 | 155 |

| Coefficient of Thermal Expansion | K⁻¹ × 10⁻⁶ | 85 | 111 |

| Thermal Conductivity | W/m·K | 0.23 | 2.96 |

| Specific Heat Capacity | J/kg·K | 2400 | 1185 |

| Melting Point | °C | 181 | 178 |

| Mechanical Properties | |||

| Tensile Strength | MPa | 122 | 53 |

| Modulus of Elasticity | GPa | 6.8 | 1.31 |

| Flexural Strength | MPa | 102.7 | 68.9 |

| Flexural Modulus | GPa | 1.38 | 1.31 |

| Hardness | — | 105 | — |

| Impact Strength | KJ/m² (Charpy) / J/m (Izod) | 10 (Charpy) | 150 (Izod) |

| Elongation at Break | % | 9 | 9.5 |

| Physical Properties | |||

| Density | g/cm³ | 1.1 | 1.0 |

| Water Absorption | % | 1.6 | 0.9 |

| Electrical Resistivity | ohm-cm | 2 × 10¹⁵ | 2.32 × 10¹⁴ |

PA11 vs PA12 – Differences Between Nylon 11 and Nylon 12

PA11 and PA12 are two closely related types of nylon (polyamide) used widely in 3D printing and manufacturing. Although their chemical structures differ by just one carbon atom, this small difference leads to meaningful variations in their properties, making each material better suited for different applications.

1. Origin and Environmental Impact

PA11 is a bio-based polymer made from renewable castor oil, making it more environmentally friendly with a lower carbon footprint. PA12 is primarily petroleum-based, which means it relies on fossil fuels and has a higher environmental impact, although some bio-based PA12 grades exist.

2. Mechanical and Thermal Properties

PA11 has a higher melting temperature of about 201°C compared to PA12’s 176°C, meaning PA11 can withstand higher heat before melting. PA11 also excels in impact resistance, showing significantly better Charpy impact strength (7.8 KJ/m² vs 4.8 KJ/m² for PA12) and much higher elongation at break (45% vs 18%), which means PA11 parts can stretch or bend more before breaking. However, PA12 has a slightly higher tensile modulus (1650 MPa vs 1600 MPa for PA11), indicating it is a bit stiffer and better at holding its shape under tension.

3. Flexural Properties

PA12’s flexural modulus is around 1500 MPa, which reflects good stiffness under bending forces. Data for PA11’s flexural modulus is often not directly available but it tends to be somewhat less stiff due to its higher flexibility.

4. Hardness and Durability

Both PA11 and PA12 have the same Shore hardness rating of 75, indicating similar surface hardness and resistance to indentation. However, PA12 is known for superior abrasion resistance and dimensional stability, especially in humid or wet conditions where it absorbs less water (0.5%) than PA11 (1.6%).

5. Chemical and UV Resistance

PA11 generally offers better chemical resistance, especially against hydrocarbons, alcohols, and detergents, and has better UV stability making it more suitable for outdoor use. PA12 resists oils, fuels, and solvents well but is less UV resistant and can degrade faster under sunlight.

6. Surface Finish and Processing

PA11 typically produces parts with a smoother surface finish, which is beneficial for aesthetic and low-friction applications. PA12 parts often have a slightly rougher texture, which can be advantageous where grip is necessary. Processing-wise, both materials require careful drying before 3D printing to avoid defects.

Nylon 11 vs Nylon 12, Which One to Choose in 3D Printing?

Choosing between PA11 and PA12 depends on the specific needs of your project and the environment where the final part will be used. Here are some detailed considerations:

Choose PA11 if:

- You want an eco-friendly material derived from renewable resources.

- Your parts require high flexibility and impact resistance, such as clips, hinges, or wearable parts that bend and flex often.

- You need a smooth surface finish for aesthetic appeal or reduced friction.

- The application involves chemical exposure or outdoor use, benefiting from PA11’s superior chemical and UV resistance.

- You require a higher melting point material for better thermal stability.

Choose PA12 if:

- You need strong, rigid parts with excellent dimensional stability, such as gears, tubes, or structural components.

- Your parts will face abrasion or wear, since PA12 has excellent abrasion resistance.

- The application involves extreme temperature variations, including very low temperatures, where PA12 maintains strength.

- Cost is a concern, as PA12 is generally less expensive and more widely available.

- You want parts with good resistance to oils and fuels, especially in automotive or mechanical environments.

Both materials are compatible with advanced 3D printing techniques like Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF), and both require proper drying before printing to ensure quality.