Ra vs Rz: Advantages, Uses, Roughness & Surface Differences

In manufacturing, machining, and quality control, surface finish is one of the most critical factors that determine how a part performs in real-world applications. From the smoothness of a medical implant to the sealing ability of a gasket or the wear resistance of an engine component, understanding surface roughness is essential. In this article, we’ll break down what Ra and Rz mean, their advantages, applications, and key differences, helping you understand which parameter is best suited for specific industries and engineering needs.

What is Ra?

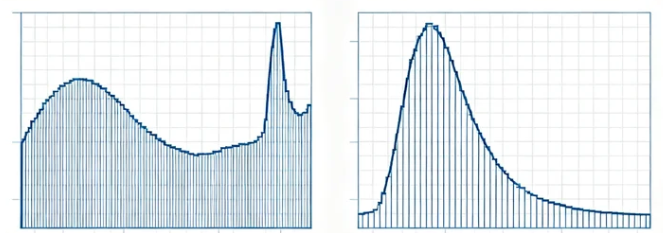

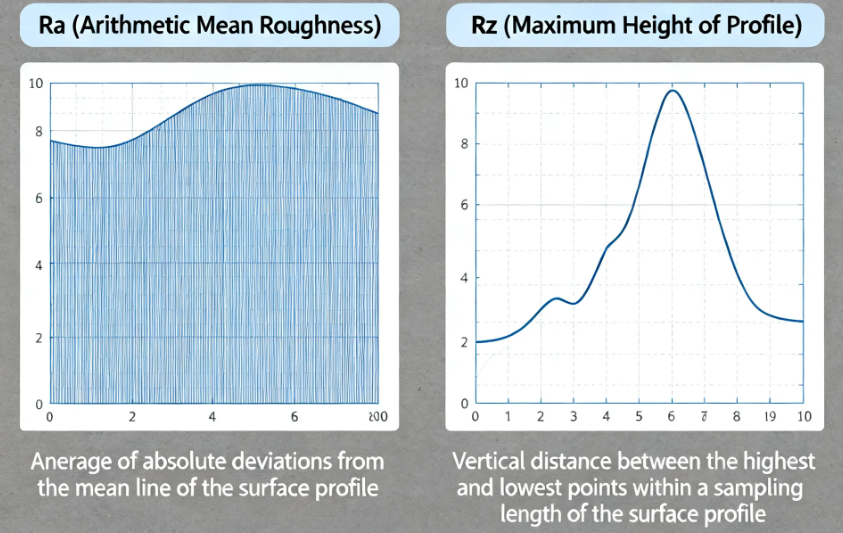

Ra, or arithmetic average roughness, is a widely used parameter in surface engineering that quantifies the smoothness or roughness of a material’s surface. It represents the average deviation of surface peaks and valleys from a mean line over a specified sampling length. Measured in micrometers (µm) or microinches, Ra provides a single value that helps engineers and manufacturers assess surface quality, friction, wear, and adhesion properties. While Ra gives a general idea of surface texture, it does not capture extreme peaks or specific patterns, so it’s often used alongside other roughness parameters for precise applications in machining, coatings, and material performance evaluation.

Advantages of Ra

Simplicity – Ra is easy to measure and calculate, providing a quick single-value assessment of surface roughness.

Widely Accepted Standard – It is recognized internationally and commonly used in engineering, machining, and quality control.

General Surface Assessment – Provides a good overall idea of surface texture and uniformity for many practical applications.

Useful for Process Control – Helps monitor machining, polishing, or coating processes to ensure consistent surface quality.

Cost-Effective Measurement – Instruments to measure Ra are widely available and relatively inexpensive compared to more complex roughness parameters.

Compatibility – Ra values can be used to compare different materials or manufacturing methods easily.

Applications of Ra

Applications of Ra (arithmetic average roughness) are widespread in manufacturing, engineering, and quality control because it provides a simple measure of surface texture. Key applications include:

Machining and Manufacturing – Used to monitor and control surface finish during turning, milling, grinding, or polishing operations.

Quality Control – Ensures parts meet design specifications for smoothness, which can affect performance, wear, and assembly.

Coating and Painting – Helps determine surface preparation requirements to ensure proper adhesion of paints, coatings, or platings.

Seal and Gasket Surfaces – Ensures surfaces are smooth enough to prevent leaks in mechanical seals or gaskets.

Friction and Wear Control – Guides surface roughness levels to optimize friction, reduce wear, or improve lubrication performance.

Medical Devices – Used to measure implant or surgical instrument surfaces where texture affects biocompatibility and performance.

Automotive and Aerospace Components – Ensures critical parts like engine components, shafts, and bearings meet roughness requirements for efficiency and durability.

What is Rz?

Rz is a surface roughness parameter that measures the average height difference between the five highest peaks and the five deepest valleys within a specified sampling length on a material’s surface. Unlike Ra, which calculates the arithmetic average of all deviations, Rz focuses on the extreme features of the surface profile, providing a better indication of peak-to-valley variations. It is commonly expressed in micrometers (µm) and is widely used in manufacturing, machining, and quality control to evaluate surface texture, ensure proper fit, reduce wear, and optimize performance in mechanical components.

Rz Advantages

Highlights Surface Extremes – Unlike Ra, Rz focuses on the peaks and valleys, providing a better understanding of extreme surface features.

Better for Functional Surfaces – Useful where peak-to-valley height affects performance, such as sealing surfaces or bearing contacts.

Sensitive to Wear and Damage – Helps detect surface defects, scratches, or irregularities that Ra might overlook.

Widely Used in Engineering Standards – Many mechanical and manufacturing standards specify Rz for critical surface quality measurements.

Improves Fit and Assembly – Ensures surfaces meet functional requirements, reducing leakage, friction, or improper mating of parts.

Complementary to Ra – Provides additional insight when used alongside Ra, giving a more complete picture of surface texture.

Rz Applications

Applications of Rz (average maximum height roughness) focus on situations where surface peaks and valleys critically affect performance. Key applications include:

Sealing Surfaces – Ensures proper contact and prevents leaks in gaskets, O-rings, and mechanical seals.

Bearing and Shaft Surfaces – Controls peak-to-valley heights to reduce wear, friction, and improve lubrication.

Mold and Die Surfaces – Ensures consistent part release, surface finish quality, and dimensional accuracy in molding processes.

Precision Engineering – Used in aerospace, automotive, and medical components where surface extremes impact fit, assembly, or functionality.

Quality Control in Machining – Detects scratches, grooves, or other irregularities that could compromise part performance.

Coating and Plating Preparation – Helps evaluate surface peaks and valleys to ensure coatings adhere properly.

Ra vs Rz, What’s the Difference?

| Feature | Ra (Arithmetic Average Roughness) | Rz (Average Maximum Height Roughness) |

|---|---|---|

| Definition | Arithmetic mean of all deviations (peaks and valleys) from the mean line over a sampling length | Average height difference between the five highest peaks and five deepest valleys over a sampling length |

| Focus | General surface roughness | Extreme peaks and valleys |

| Sensitivity | Less sensitive to occasional deep scratches or high peaks | More sensitive to surface irregularities and defects |

| Unit | Micrometers (µm) or microinches | Micrometers (µm) or microinches |

| Best For | Overall surface texture assessment | Functional surfaces where peak-to-valley height matters (e.g., seals, bearings) |

| Common Applications | General machining, coatings, aesthetic surfaces | Bearings, gaskets, shafts, mold surfaces, critical mechanical parts |

| Advantage | Easy to measure and widely standardized | Provides better insight into extreme surface features that may affect performance |

Ra vs Rz Roughness

Ra (Arithmetic Average Roughness)

Definition: Ra represents the average of all surface deviations (peaks and valleys) from the mean line over a measured length.

Focus: Provides a general indication of overall surface smoothness.

Sensitivity: Less sensitive to extreme peaks or deep valleys; occasional scratches have minimal effect.

Best Use: General machining, coatings, and aesthetic surface quality assessment.

Measurement: Commonly in micrometers (µm) or microinches.

Rz (Average Maximum Height Roughness)

Definition: Rz is the average height difference between the five highest peaks and five deepest valleys within a sampling length.

Focus: Highlights extreme surface features, not just the average texture.

Sensitivity: Highly sensitive to scratches, grooves, or irregularities that Ra might overlook.

Best Use: Functional surfaces where peak-to-valley height affects performance, such as bearings, seals, shafts, and molds.

Measurement: Also in micrometers (µm) or microinches.

Ra vs Rz Surface Finish

Ra (Arithmetic Average Roughness) and Surface Finish

Definition: Ra measures the average deviation of surface peaks and valleys from a mean line over a defined length.

Effect on Surface Finish: Provides a general sense of smoothness; a lower Ra value indicates a smoother surface.

Applications: Commonly used for general machining, polishing, coating preparation, and aesthetic surfaces where overall smoothness matters.

Rz (Average Maximum Height Roughness) and Surface Finish

Definition: Rz measures the average of the vertical distance between the five highest peaks and five deepest valleys in the sampling length.

Effect on Surface Finish: Highlights surface extremes; even if Ra is low, a high Rz indicates some deep grooves or high peaks that may affect performance.

Applications: Critical for functional surfaces like sealing faces, bearings, shafts, and molds where peak-to-valley heights impact performance.